prefabrication

Pan-Pacific prefabricates nearly everything in-house for our projects, often collaborating with other subcontractors to add efficiencies. Our prefab process makes material ready for installation within minutes of its delivery on-site minimizing field labor, storage and waste while keeping the assemblies in a controlled environment to promote safety, enhance quality control, reduce costs and increase the overall productivity.

innovative use of bluebeam

In 2014, Pan-Pacific Mechanical won the Bluebeam eXtreme Award for Innovative use of the program. On the Wilshire Grand Project, Pan-Pacific created a way to stream-line building color composite drawings using the power of Studio and the process is now being used on many high-profile projects such as LA Rams Stadium. This process has proven to save over 2,000 man hours on previous projects. Since then, Pan-Pacific has pushed to integrate the program company-wide including housing all field deliverables into studio projects which can be accessed from our IPAD’s in the field. After fully integrating Bluebeam Studio API into our Internal Scheduling Portal, we have taken our Bluebeam Revu game to the next level. This past year, we trained nearly 200 of our Field and Office staff on the program streamlining workflows and really leveraging the best of the program in all departments across the company.

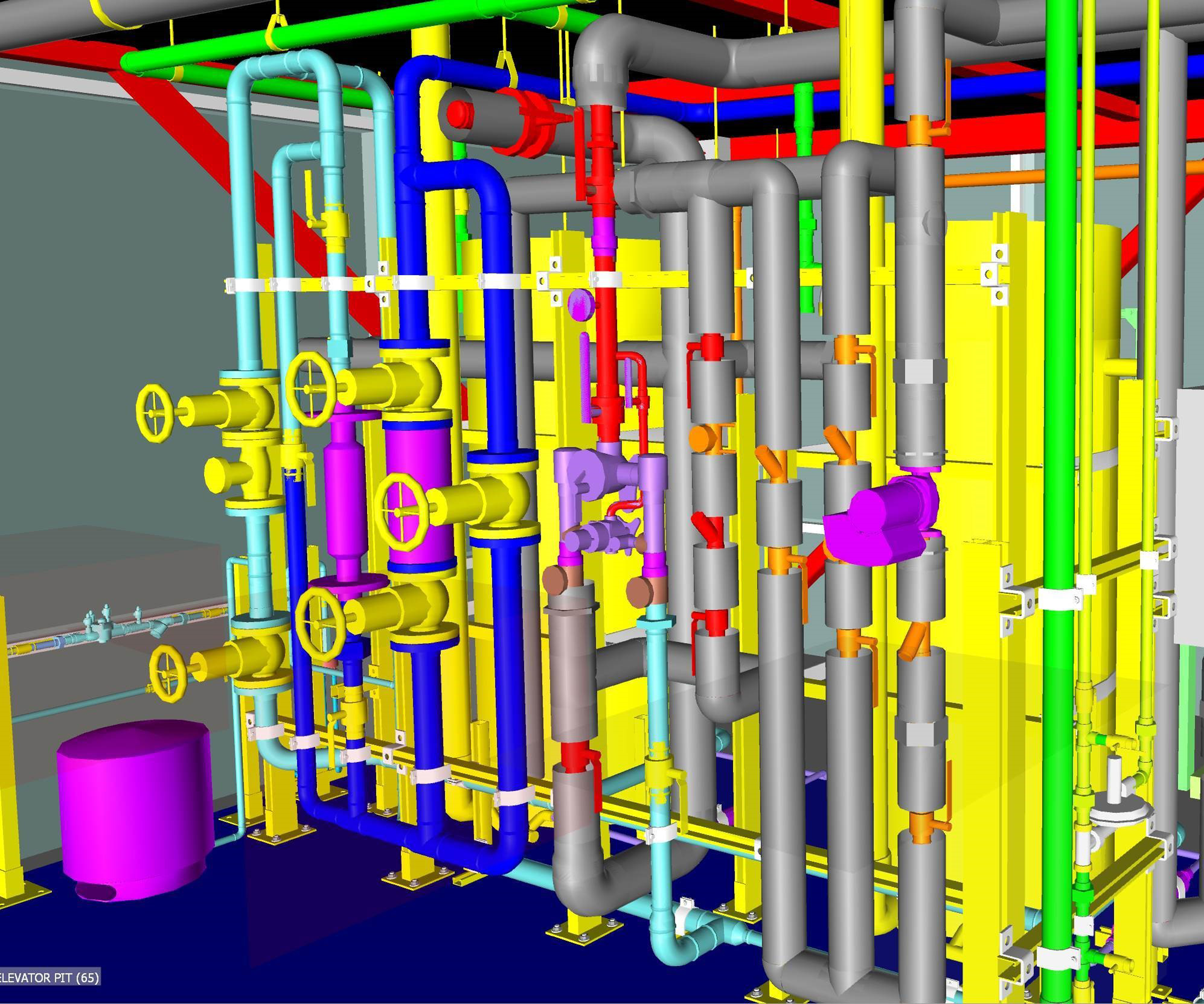

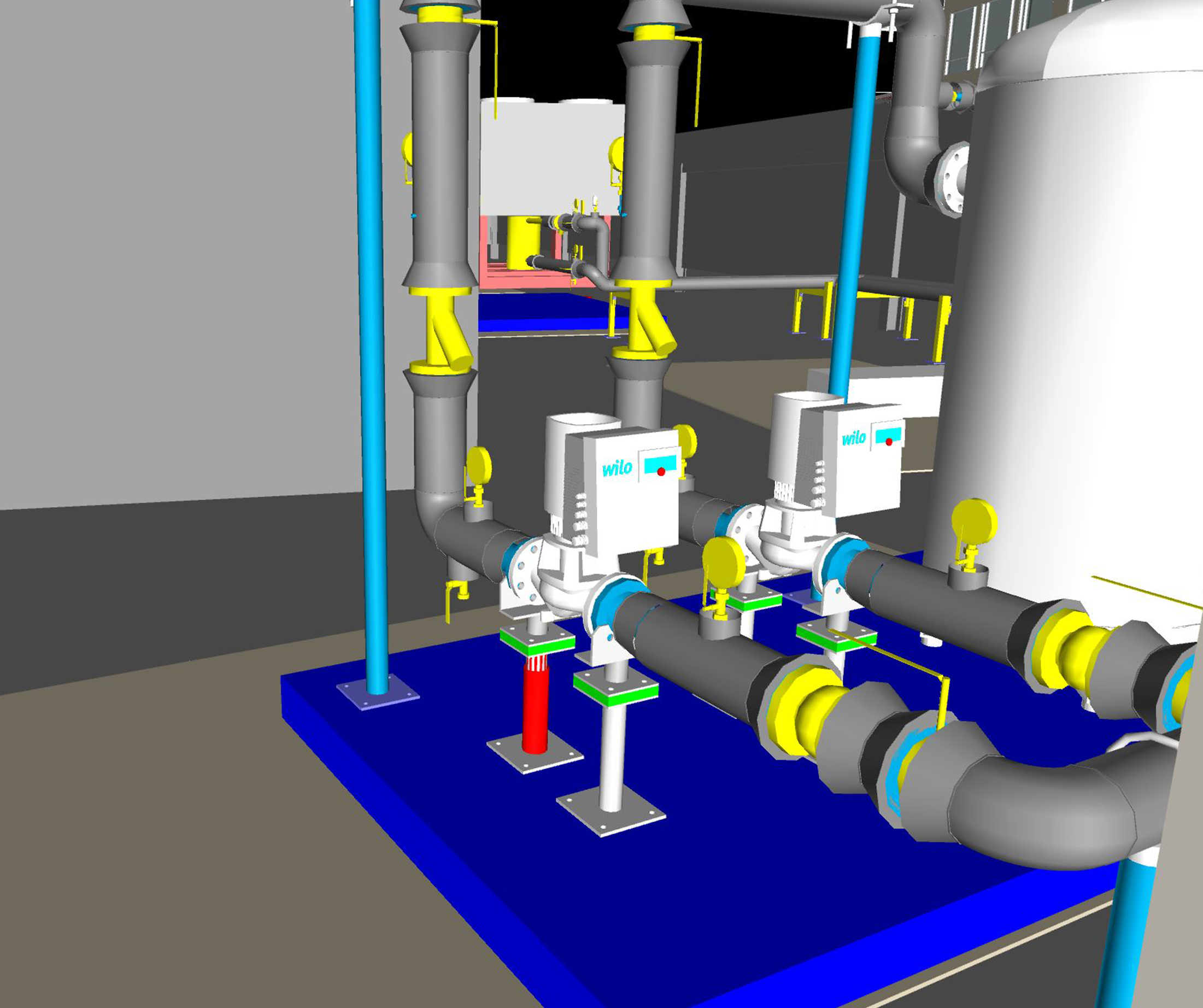

Virtual Preconstruction

Our detailers create 3D drawings with a high level of accuracy allowing our model to be a direct reflection of what is installed in field using the most advanced modeling tools available. The entire project is modeled using the specifications and the materials required for the project. The same 3D shop drawings that create the model are used use to coordinate fabrication, installation and eventually turnover. At the completion of the project the owner will have peace of mind knowing the documents they receive are exactly what was installed and feel confident in giving those drawings to the operations and maintenance personnel.

Our Tools & Technology

- AutoCAD 2D

- AutoCAD Fabrication MEP

- REVIT

- Navisworks

- Trimble

- LEED Online

- Energy Pro

- Trace

- Bluebeam/Extreme/Studio

- Mobile Field Access